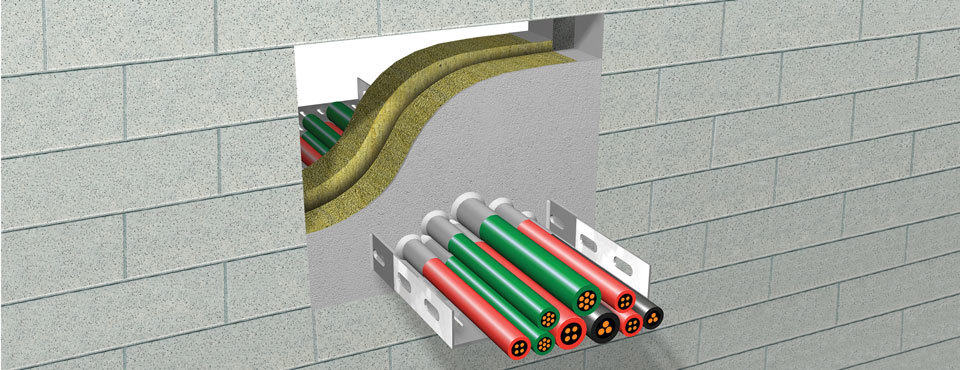

Cables, cable bundles, conduits, bundles of conduits, empty pipes, cable trays and cable ladders may also pass through penetration seals in walls and floors and should be taken into consideration during all phases of design and application. The last part of our penetration seal series of articles clarifies some general aspects of cable penetrations.

Cable Groups

Cable penetrations are tested according to European Standard EN 1366-3 and the results are classified according to EN 13501-2. It is very important, albeit less known, that the cables are classified into six different cable groups according to the most frequent cable types and configurations:

| Cable types | Configuration |

| Cable Group 1 | small sheathed cables on their own or bundles of cables with an outer diameter not exceeding 21 mm (Ø ≤ 21 mm), e.g. 10 pieces of 5 mm x 1,5 mm2 or 2 pieces of 1 mm x 95 mm2 cable dimensions (see details in the Standard) |

| Cable Group 2 | medium sheathed cables with an outer diameter of 21 mm < Ø ≤ 50 mm e.g. 1 piece of 4 mm x 95 mm2 or 2 pieces of 1 mm x 185 mm2 cable dimensions (see details in the Standard) |

| Cable Group 3 | large sheathed cables with an outer diameter of 50 mm < Ø ≤ 80 mm e.g. 1 piece of 4 mm x 185 mm2 cable dimensions (see details in the Standard) |

| Cable Group 4 | a bundle of cables from group 1 with the largest diameter not exceeding 100 mm (telecommunication cable) Ø ≤ 100 mm |

| Cable Group 5 | non-sheathed cable types (wire, H07V-R), Ø ≤ 24 mm, e.g. 1 piece of 1 mm x 95 mm2 or 1 piece of 1 mm x 185 mm2 cable dimensions (see details in the Standard) |

| Cable Group 6 | steel, copper or plastic conduits or tubes (empty tubes) three in a bundle, the configuration of the tube is U/C (uncapped in the furnace, capped outside of it), Ø ≤ 16 mm |

When testing, each cable group is placed according to the configuration described in the Standard, and the tested cross section, the distance from each fitting and from the building structure are taken into consideration. If the customer does not wish to have classifications for all the groups, then these groups are left out of the specimen.

Soft penetration seals

We will not describe the products in general but instead the penetration systems, like we did for the pipe penetration seals. The most widely known systems are the so-called soft penetration seals. They are a combination of mineral wool of a specific bulk density and thickness and a fire-retardant coating (and possibly a mastic).

The fire resistance of a specific penetration seal system can be classified only by those cable groups in which it has met the requirements of the fire test. Not all cable penetration seal systems can be used as fire protection closure for cable bundles of any type and configuration.

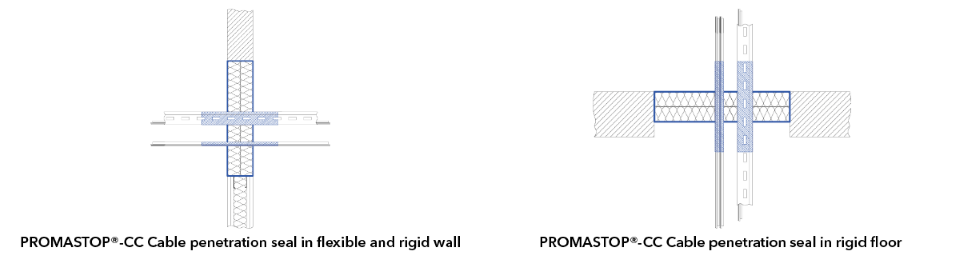

However, it is very important that the classified fire resistance of a system depends on the mineral wool used, type of installation and cable groups. The table below represents the classified fire resistance of a soft penetration seal made with Promat’s water-based ‘hybrid’ PROMASTOP®-CC fire-stopping coating applied on mineral wool (density ≥ 140 kg/m3).

| Electrical installations | Thickness and orientation of mineral wool boards | |||||

| 1 × 50 mm | 1 × 80 mm | 2 × 50 mm | ||||

| Wall | Floor | Wall | Floor | Wall | Floor | |

| CG 1: All sheathed cable types Ø ≤ 21 mm | EI 60 | EI 90 | EI 90 | EI 90 | EI 120 | EI 120 |

| CG 2: All sheathed cable types 21 < Ø ≤ 50 mm | EI 60 | EI 60 | EI 60 | EI 90 | EI 90 | EI 90 |

| CG 3: All sheathed cable types 50 < Ø ≤ 80 mm | EI 60 | EI 60 | EI 60 | EI 90 | EI 90 | EI 90 |

| CG 4: Cable bundles made of cables from CG 1 Ø ≤ 100 mm | EI 60 | EI 90 | EI 90 | EI 90 | EI 120 | EI 120 |

| CG 5: Non-sheathed cable types Ø ≤ 24 mm | EI 45 | EI 60 | EI 60 | EI 60 | EI 90 | EI 90 |

| CG 6: Empty conduit/pipe made of steel, copper or plastic with pipe end configuration U/C, Ø ≤ 16 mm | EI 45 | EI 45 | EI 60 | EI 60 | EI 90 | EI 90 |

| CG … Cable group acc. to EN 1366-3:2009 | ||||||

The table shows that penetration seals of all cable groups were tested with PROMASTOP®-CC. It is advisable to consider the fact that a thicker mineral wool is needed for higher fire resistance, and that in general the classified performance is lower in cases with a higher number of cable groups.

The required thickness of PROMASTOP®-CC coating depends on the cable group, as shown in the table below:

| Object | Dry film thickness (mm) | Coating length (mm) |

| Cable group 1 - 5 | 1 | 100 |

| Cable group 1 - 6 | 3 | |

| Cable trays, cable ladders | 1 |

We must not forget that conduits are in Cable Group 6. Metal conduits conduct heat well, so a thicker (larger amount of) coating is needed to achieve suitable cooling (insulation). Additionally, a larger amount of coating is needed to fill the place of the melting plastic conduits than for the average cables (in this case PROMASTOP®-CC coating must be applied in a 3 mm dry film thickness instead of 1 mm).

The cross section of PROMASTOP®-CC soft penetration seals can be up to 3,75 m2 in walls and floors, which makes it possible to establish fire compartments in shafts with large cross sections. The coating resists moisture, so it can be used in wet areas and areas with high humidity as well, which cannot be said about other soft penetration seals.

Mixed Penetration seals

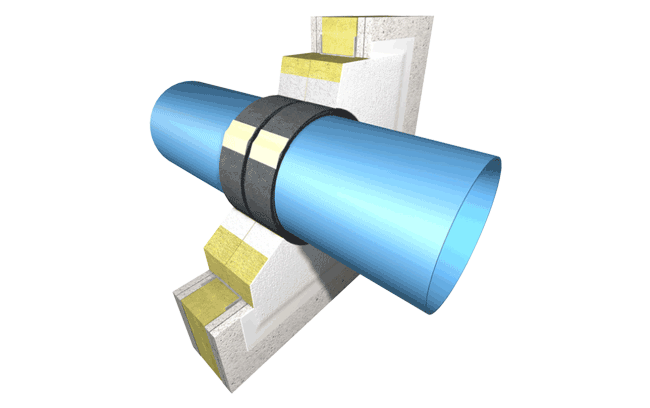

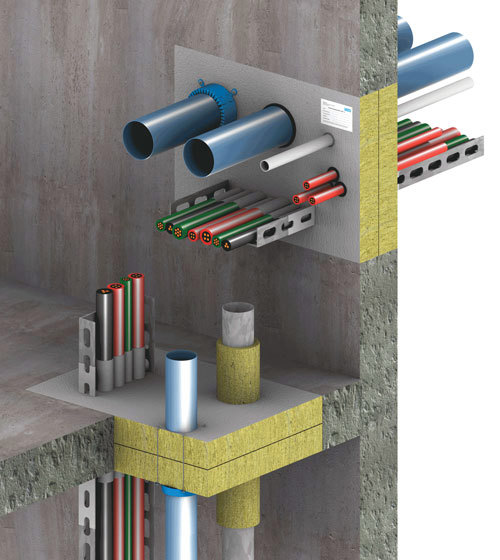

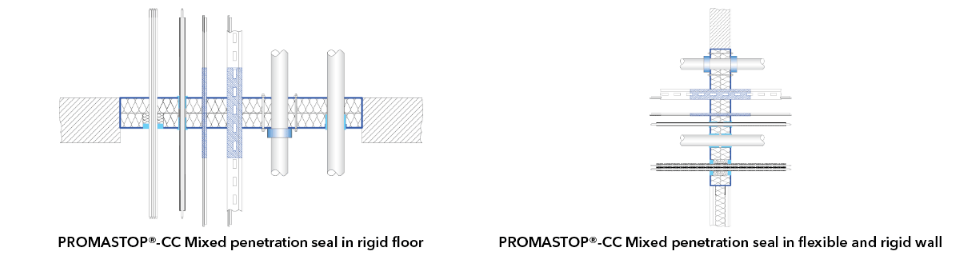

In practice, cables and pipes are often applied jointly in one penetration – these systems are called mixed penetration seals.

PROMASTOP®-CC soft penetration seals are also classified for the above-described system, with the details shown in the following drawings.

Penetration seals are an extremely broad and complicated topic because every system must be rigorously tested and certified, including thousands of different combinations of fire-stopping products and materials (pipes, cables). Therefore, we kindly invite you to contact our technical team. We will be happy to answer any questions you may have about your projects.