Promat FENDOLITE® MII re-affirms its suitability for Modular Fire Proofing Projects after passing demanding durability test for sea transportation of fire proofed modules.

At the request of global EPC Samsung Engineering Co.,Ltd, Promat's cementious spray Promat FENDOLITE® MII has been subjected to rigorous testing designed to simulate the ordeal of transporting modules from the steel fabricator to the construction site no matter where that might be in the world.

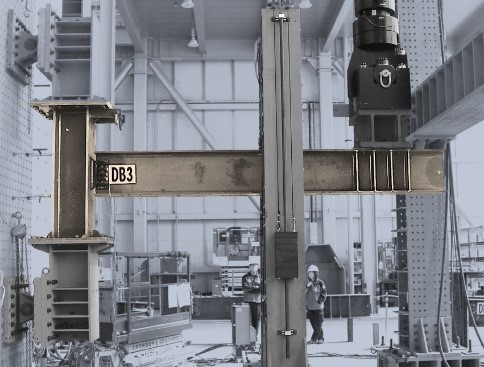

Designed to simulate challenging and demanding sea transportation conditions from Asia to USA, a distance of approximately 22,000 km, the test rig applied cyclic load, flexural strain for a duration of one and a half months to the Promat FENDOLITE® MII test specimens.

Only after successfully completing part 1 of the test was the Promat FENDOLITE® MII test specimens then subjected to one final test – pull off adhesion tests in accordance with IBC code for Sprayed Fire Resistance Materials (SFRM).

Promat FENDOLITE® MII already has a fantastic track record with modular construction projects, having recently successfully completed the Sriracha Refinery, which is part of Thai Oil’s Clean Fuel Project (CFP), this fantastic test result can only serve to further strengthen the argument for cost effective fire proofing with Promat FENDOLITE® MII.

Advantages of modular construction

Modular construction involves prefabricating equipment and systems into modules offsite in a controlled manufacturing facility. Once constructed, the modules are delivered to the building or production site where they can be installed and commissioned. This approach is increasingly being applied to chemical, refining, LNG facilities, onshore and offshore production projects.

Modular construction offers several advantages over traditional stick-built methods of construction where most of the work is performed onsite.

Reliable Access to Skilled Manpower

Modular construction offers access to the type of workers required to build large-scale facilities. In many instances, an offsite module fabrication facility can be selected in a region or country where the labour supply and demand relationship are more balanced, allowing the operator to take advantage of lower rates.

Shorter Development Schedule

A project’s development schedule can be significantly reduced. By assembling modules using prefabricated parts offsite in a designated facility, the chance of running into delays caused by weather or other environmentally related factors is minimised. Building offsite also affords operators the advantage of being able to perform work on multiple areas of a facility simultaneously such as fireproofing the module with Promat FENDOLITE® MII. This is not always possible when using the traditional stick-built approach.