Fire doors are key to guaranteeing fire safety in domestic and commercial buildings, saving lives and limiting fire damage. They prevent the spread of fire and smoke from one space to another, protect occupants in other parts of the building, and provide a safe escape route. In the event of a fire, they are a crucial ally for fire brigade and other emergency services. But how do you develop a fire door that offers guaranteed levels of fire protection and has great aesthetic value at the same time?

The pioneer in passive fire protection and fire door applications

Promat has played a pioneering role in the European fire door market since the 1970s. For many years we have supported leading fire door manufacturers across the continent, co-creating doors that have tremendous commercial success, answer to the most stringent fire regulations and provide reliable protection.

Our extensive knowledge and expertise in passive fire protection - in building and industrial applications - and long-term partnership with fire door manufacturers gives us an in-depth understanding of how fire behaves and how the different components and materials used in fire doors interact with fire.

Backed by an extensive and proven range of fireproofing products, a complete range of technical and workshop services and a dedicated team of specialist, we are able support our customers at each phase of their development process. No matter how complex the challenge might be, we make sure that all angles are covered and that we create a solution together.

The calcium silicate difference: a wide range of certified and proven materials

To contain a fire and to prevent it from spreading to other spaces, a fire door needs to prevent heat transfer, seal off smoke and maintain its shape and structural integrity. Here’s where Promat’s expertise, solutions and services make the difference.

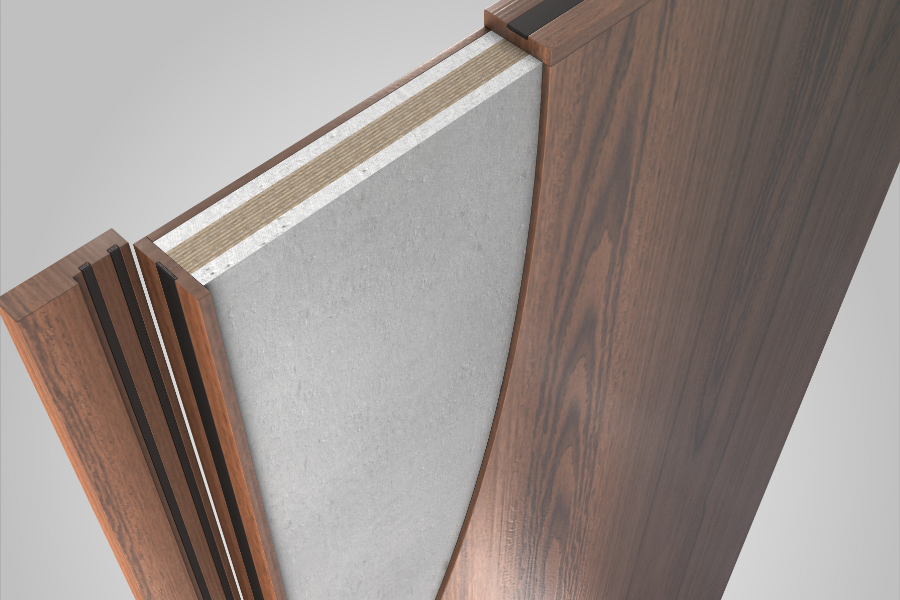

Our A1 non-combustible calcium silicate boards have a proven track record in fire door applications. They are tested and certified to international standards and provide a reliable and sustainable solution in all temperature conditions – even when used in wet or damp areas or in places where chemicals are used, like laboratories, storage rooms or processing units. These purpose-designed fire protection boards prevent heat transfer thanks to their unique heat storage and insulation properties. Moreover, with an exceptionally low shrinkage of less than 2% our calcium silicate boards maintain their structural stability and minimise fire door and door frame distortion during and even after a fire.

Another great advantage is the limited thickness of our calcium silicate boards, which offer greater design flexibility without compromising on performance or service life. Their reduced weight will also minimise strain on the hinges to maintain a closed gap and will allow for a more ergonomic installation, shipping and handling.

Guaranteed levels of fire safety with a combined calcium silicate and intumescent solution

To provide guaranteed levels of fire safety, and complementary to our calcium silicate boards, we offer a comprehensive range of intumescent firestopping seals. These materials have a proven life expectancy of more than 30 years and are the perfect fit for frames, door closers and locks (in timber, aluminium and steel doors). They provide a secure seal against the spread of fire and gas and expand up to 20 times their own volume when exposed to temperatures starting from 150°C upwards.

A combined solution of Promat’s calcium silicate boards and intumescent firestopping seals will offer a durable protection that will stand the test of time and will enable you to pass your fire inspections and keep people safe year after year.

The right solution for the right type of fire door

From our long-term experience in passive fire protection, we know that some boards are better suited to reduce temperatures, because of the cooling effect they create when exposed to heat. Other boards are ideal to prevent heat transfer, because of their minimum shrinkage and structural stability. There are many different variables that will define which material to use in a specific type of fire door. Based on the application, the required fire-rating (60, 90 or 120 minutes) and all other technical and commercial requirements, we will come up with the ideal solution together with you.

Dedicated fire protection services from concept to fire testing and assembly

We develop and optimise our range of fireproofing materials in close collaboration with the market. This approach enables us to develop systems and solutions that answer to or even exceed our customers’ expectations. Each fire door manufacturer has different requirements, and you need a manufacturer that understands your unique challenges and operating environment. Promat is much more that a supplier. We study and understand your needs and adapt to support your process improvements and strategic goals.

To ensure we achieve an optimal result we can support you at each stage of your project – from initial concept to fire testing and, finally, assembly. Depending on your requirements we can assist you with your application design, provide consultancy, organise fire testing for a wide range of scenarios at our in-house facilities or at external labs, and provide workshop services to deliver ready-to-install components.

With Promat as your preferred partner you will benefit from more than 60 years of experience and know-how in passive fire protection to stay at the cutting edge of your industry.

Promat’s commitment to sustainable production

Promat is committed to reducing its carbon footprint and actively contributing to the circular economy. At our production site for calcium silicate boards for fire doors, we aim to make the production process as sustainable as possible.

By producing most of our power on-site at our manufacturing plant and by using heat to generate the steam required for our production cycle, we are able to reduce our use of primary energy by 15%. What’s more, we have rolled out two solar parks with a total surface of 30,000 m², with each park generating 1 MWp.

We reuse almost all waste materials from our boards (sanding dust, edge trimming and rejected boards) in new product mixes. During the production cycle we use water from a nearby canal, as opposed to potable or ground water. Thanks to several sedimentation tanks and dedicated water treatment systems we can reuse this water several times and reduce our water consumption dramatically.

At Promat we go the extra mile to put our sustainability ambitions into practice.

Keeping our finger on the pulse

The world is rapidly evolving, and we are facing many challenges. By keeping our finger on the pulse of the latest developments in the market we ensure that together with our customers we can make the difference. As we are part of the Etex group, a large Belgian industrial group specialised in building materials, you will have access to a complete portfolio of building products and solutions. No matter if you are working on a local project or if your project involves multiple stakeholders in different countries or on different continents, Promat is here to help you inspire ways of living in a safer, more sustainable world.