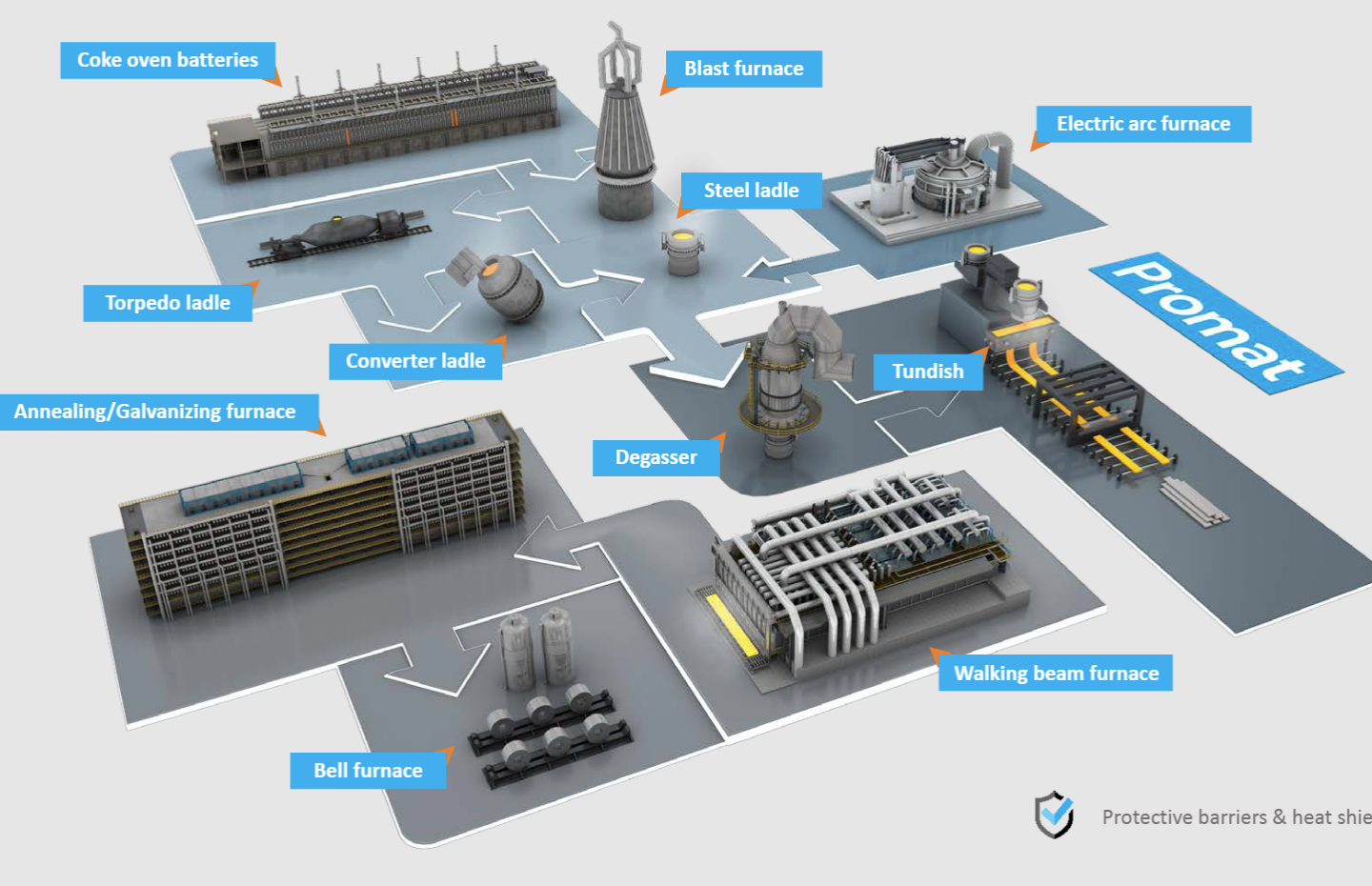

Tailored, expert solutions for steel processing challenges

In downstream processing, precision, speed, and reliable performance are essential. Industrial furnace manufacturers need a partner who truly understands the technical demands of their processes and can offer the right solutions without compromise.

Promat brings exactly that. With deep expertise in high-performance insulation materials for downstream applications, we work alongside customers to propose tailored, cost-effective solutions for their industrial furnaces. From fast installation to process optimization, we deliver proven value backed by technical know-how and decades of industry experience. Download our brochure and discover our wide range of insulation solutions.

Your trusted partner for full-range insulation solutions

We provide trusted solutions for the upstream steel industry and bring the same expertise to downstream steel processing companies, where they often struggle with sourcing the right materials and coordinating multiple suppliers. Promat streamlines this by offering a complete range of solutions from a single, reliable partner.

With our European production site, we ensure quick access to high-quality materials, tailored to meet your specific requirements. By partnering with us, you gain the benefit of comprehensive support and expertise, streamlining your processes and reducing costs.

Cut heat loss by 40% in reheating furnaces

Reheating furnaces for rolling mill, like walking beam furnace and forging furnace, consume large amounts of energy, much of which is lost through outdated insulation. Promat significantly reduces that loss by up to 40%, delivering up to 40% savings in both energy cost and CO2 emissions, and better temperature control. With reduced surface temperatures and no added thickness, it’s a compact upgrade that improves safety, efficiency, and your environmental footprint.

Optimize furnace operations and reduce CO2 emissions by 25%

Heat treatment furnace types, such as tempering furnaces, annealing furnaces, and hardening furnaces, often struggle with high heat loss, excessive fuel consumption, and increasing operational costs. Promat’s solution reduces heat loss, fuel consumption, and CO₂ emissions by 25%, improving energy efficiency and lowering operational costs. It also ensures better temperature control, faster heat-up and cooling, and enhanced safety by reducing shell temperatures, all while supporting sustainability and reducing the overall carbon footprint.

Achieve 30% energy savings in galvanizing furnace

Galvanizing lines run at high temperatures, often wasting energy through inefficient insulation. This not only drives up fuel costs but also increases emissions and slows down thermal cycles. Promat insulation tackles this challenge by reducing heat loss by up to 30%, cutting energy use and CO₂ emissions by 30%, and lowering surface temperatures by 15%. The result: faster heating and cooling, safer operations, and long-term cost savings, without increasing the lining thickness.

Why choose Promat as your trusted partner?

Complete solution from one trusted partner

![]()

Up to 30% energy savings

Built to endure extreme heat