In the first part of our series of articles we dealt with penetration seals of metal pipes, non-combustible pipe insulations (CS, CI, LS or LI arrangements), possible pipe end configurations (U/U, U/C, C/U, C/C) and with the hanging and support distances of assemblies. In this part we write about pipes made of combustible materials, penetration seals of multi-layer composite pipes and combustible pipe insulations. Furthermore, we would like to call designers, installers, contractors and firefighter colleagues’ attention to some (not yet widely known!) basic rules, which have to be taken into account during design, installation and inspection.

Plastic pipes

Interestingly, pipe penetration seals made from combustible materials cause less problems than seen with metal pipes, but the basic principles are the same: information referring to the application of the penetration in specific installation positions can be found in the classification and technical documentation (manual) of the given product.

The most important parameters are the following:

- fire classification;

- material and wall thickness of the pipe;

- material, thickness and arrangement of the insulation;

- pipe end configurations;

- type and minimal thickness of the building structures affected by the pipe penetration (flexible or rigid wall, rigid floor, cross laminated timber wall or floor, suspended ceiling or sandwich panel structure);

- dimension limitations;

- distances of the objects and;

- fixings (all the details will be discussed later).

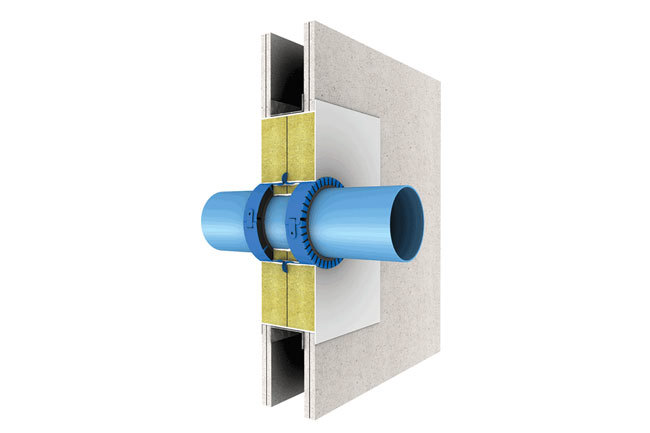

It is obvious that the area of a melting combustible pipe (and the heat insulation as well) must be sealed by an intumescent material.

Certain listed products might be combined with coatings like PROMASTOP®-CC and PROMASTOP®-I for soft penetrations or with PROMASTOP®-M fire-stopping mortar for hard penetrations. Some of the application methods are presented in this article, and the complete application guide is available in the DocumentationDownload section or by contacting our local office.

The size of the penetrating plastic pipe must be taken into account with all products and penetration types. Here are some examples of the most commonly used penetration types, that are made either with PROMASTOP®-CC soft penetrations:

- PROMASTOP®-FC6 fire-stopping collar: PVC-U and PVC-C pipes up to Ø 250 mm, PE-HD (or HDPE), ABS, SAN+PVC, PP-H and PP-R pipes up to 200 mm.

- PROMASTOP®-W fire-stopping wrap: all the above pipes up to Ø 160 mm.

- PROMASEAL®-AG fire stopping acrylic in core drilled hole is classified for closing penetrations of PVC-U pipes with a maximum diameter of 110 mm and 3.2 mm pipe wall thickness or PP pipes with a maximum diameter of 50 mm and 1.8 mm pipe wall thickness; the swelling capacity of the product is suitable for filling the whole cross section of the pipe when the maximum 20 mm wide annular gap around the pipe is filled with minimum of 25 mm or 20 mm depth, respectively.

Material of the combustible pipe

Tests based on the EN 1366-3 Standard must be performed separately for PVC-U and PE-HD pipes as well. According to the Test Standard, the test results of PVC-U pipes manufactured on the basis of the EN 1329-1, EN 1453-1 or EN 1452-1 Standards are valid for PVC-C pipes manufactured on the basis of EN 1566-1, as well. The results of PE-HD pipes manufactured on the basis of the EN 1519-1 or EN 12666-1 Standards can be used for PE pipes manufactured according to the EN 12201-2, EN 1519-1 or EN 12666-1 Standards, and for acrylonitrile butadiene styrene (ABS) pipes made on the basis of the EN 1455-1 Standard, and for styrene copolymer mixture (SAN+PVC) pipes manufactured according to the EN 1565-1 Standard.

Wall thickness of plastic pipes

According to the EN 1366-3 Standard, the pipe types to be tested are divided into dimension groups based on diameter and wall thickness (e.g. Dimension Group 1: 50-80 mm pipe outer diameter and 3-6 mm pipe wall thickness; Dimension Group 2: 90-125 mm pipe outer diameter and 3-8.6 mm pipe wall thickness, etc.). A certain type of collar can only be used for the dimension group for which it had positive test results.

Combustible insulation on pipes made from combustible material

In practice, pipes are usually equipped with insulation made from combustible materials to provide thermal or acoustic insulation. This fact must be taken into consideration when testing the collars. As shown in the example table shown below, PROMASTOP®-FC3 or PROMASTOP®-FC6 fire collars were classified from EI 60-U/U up to EI 120-U/U with Geberit Silent PP pipes in the range of Ø 32 mm / s 2.0 mm - Ø 160 mm / s 32.0 mm (s: pipe wall thickness).

| Requirement | Dimension range Ø…Pipe diameter (mm) s…Pipe wall thickness (mm) d…Insulation thickness (mm) |

Classification | |||

| Rigid wall | Rigid floor | Plywood board wall | Plywood board floor | ||

| Geberit Silent PP pipes for pipe bushings at 90° | |||||

| Collar surface-mounted, construction thickness ≥ 140 mm | Collar surface-mounted, construction thickness ≥ 140 mm | PROMASTOP®-FC3 Ø 32 mm, s 2,0 mm R Ø 125 mm, s 4,2 mm PROMASTOP®-FC6 Ø 32 mm, s 2,0 mm R Ø 160 mm, s 5,2 mm |

EI 90-U/U | ||

| Collar surface-mounted, construction thickness ≥ 100 mm Collar built-in, construction |

Collar surface-mounted, construction thickness ≥ 150 mm Collar built-in, construction |

EI 120-U/U | |||

| Collar surface-mounted, construction thickness ≥ 150 mm | PROMASTOP®-FC6 Ø 32 mm, s 6,0 mm R Ø 160 mm, s 32,0 mm |

EI 60-U/U with combustible insulation B-s3, d0 |

|||

| Collar surface-mounted, construction thickness ≥ 150 mm | PROMASTOP®-FC6 Ø 32 mm, d 6,0 mm R Ø 160 mm, d 6,0 mm |

EI 120-U/U with combustible insulation B-s3, d0 |

|||

| Collar surface-mounted, construction thickness ≥ 100 mm | PROMASTOP®-FC6 Ø 32 mm, d 6,0 mm R Ø 160 mm, d 32,0 mm |

EI 120-U/U with combustible insulation B-s3, d0 |

|||

Metal pipes with combustible insulation

The penetration seals of metal pipes were discussed in the previous article, although combustible insulation wasn’t mentioned there.

EI 120-U/C fire classification can be achieved by PROMASTOP®-B fire-stopping bricks that are used for the penetration of steel pipes with a maximum of 220 mm pipe outer diameter and 18 mm wall pipe thickness, equipped with insulation that has a maximum of 32 mm thickness, and B-s3, d0 reaction to fire classification. The penetration seals of copper pipes with a maximum of 88.9 mm pipe outer diameter and 14.2 mm wall pipe thickness were classified for EI 90-U/C with the same insulation. Please note that the thermal conductivity factor of the pipe wall material is of vital importance (this factor was discussed in our previous article) – lower fire performance was achieved with the same penetration solution for copper pipes with better thermal conductivity, smaller diameter and smaller wall thickness.

Multi-layer composite pipes with combustible insulation

Penetrations of aluminium composite pipes (Pipelife RADOPRESS) with PE-X/Al/ PE-X chemical labels and combustible insulation can be sealed with PROMASTOP®-W fire-stopping wrap in PROMASTOP® soft penetrations. There are two possible insulations:

- B-s3, d0 reaction to Fire Classification according to EN 13501 e.g. caoutchouc, ≥ 6 mm ≤ 32 mm thickness;

- E reaction to Fire Classification according to EN 13501 e.g. PE ≥ 4 mm ≤ 9 mm thickness;

| Soft seal (mm) | Orientation F…Floor W…Wall |

Dimension range Ø…Pipe diameter (mm) d…Insulation thickness (mm) |

L…Number of layers (wrap) | Classification | |

| Pipelife Radopress pipes | |||||

| 2 × 50 | F / W | Ø 16 mm, d 6,0 mm RØ 63 mm, d 32,0 mm | 1 | EI 120-U/C with combustible insulation B-s3, d0 | |

| 2 × 50 | F / W | Ø 16 mm, d 4,0 mm RØ 32 mm, d 9,0 mm | 1 | EI 120-U/C with combustible insulation E | |

In our next article we will focus on electric systems of the buildings, because cable installations are exposed to special risks and are worth some special attention. We will discuss issues that need to be considered during the construction process – mostly regardless of the product you choose. The planned final part of our fire-stopping series of articles describes penetration seals for cables, cable bundles and linear joints (gaps).