Fire rated ductworks are very important element of fire safety system in buildings. Depending on its role, we can distinguish two main types: smoke extraction ductworks and ventilation ductworks.

Smoke extraction ductworks

Smoke extraction ducts are used to remove smoke from buildings, to enable emergency evacuation of the occupants as well as improved firefighting and flash over prevention.

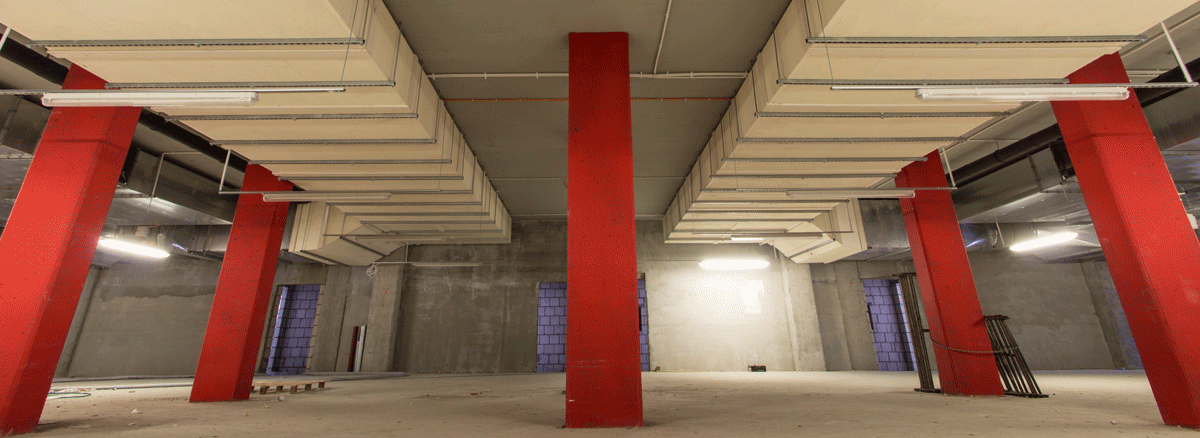

They are mainly used in large compartment, car parking, high-rise building and atriums in commercial, office and residential buildings. Car parks with low ceilings present dangerous zones because the smoke layer can fill the space very quickly and prevents evacuation. High compartments (typically greater than 15 m) are vulnerable to spreading smoke and present a challenge for fire protection engineers because of the decreased effectiveness of automatic sprinkler systems.

Fire rated ductworks are required to conduct the smoke outside from the building, even using fan assisted systems. If a smoke extraction ductwork is wholly contained within a fire compartment, it must at least be capable of resisting the anticipated smoke temperatures generated during the development of a fire. If the ductwork penetrates a fire resisting barrier (such as a fire rated partition or ceilings), it must also be capable of providing the same fire resistance of the barrier.

From an effective smoke removal point of view, it is necessary to subject the room in question to a detailed analysis in terms of the fire propagation velocity, floor surface area, and height.

Fire rated ventilation ductworks

Fire rated ductworks are used to guarantee the fire compartmentation. More precisely, fire rated ventilation ducts can avoid fire and heat spread between two compartments.

It is possible to prevent fire spread from one fire compartment to another, along stairways, rooms and general access corridors, only if all building materials and structural elements share a common fire classification and fire resistance rating.

Compartment walls and floors must have a certain fire resistance, which means that the performance criteria of load-bearing capacity (stability), integrity and insulation have been met for a duration of 30 to 240 minutes. It is therefore extremely important that, where compartmentation boundaries are penetrated by services, the fire separation criteria for the penetrated elements are maintained and, in particular, that ducting should not become a conduit along which fires, or hot smoke, may spread to other areas.

The view on risk of smoke spread in ventilations systems varies throughout Europe. In some countries smoke spread via the ventilation system is not considered to be a problem at all, in other countries smoke dampers or fire/smoke dampers are always required where there are more than one fire compartment supplied by the same system. Finally, there are countries where the regulations in addition to fire/smoke dampers also allow performance-based design.

In any case, the fire performance of a duct which penetrates a fire resisting/separating element must requires careful consideration by specifiers. Typical metal sheet ducts fail to meet internationally accepted fire protection requirements. They heat and deform rapidly from the effects of fire. Under specific circumstances they can even accelerate the spread of flame and smoke.

What is the best ductwork system for my project?

Choosing the right fire rated ductwork is difficult due to complexity of the duct construction (passing through different fire compartments), function of the system in the ambient and fire conditions.

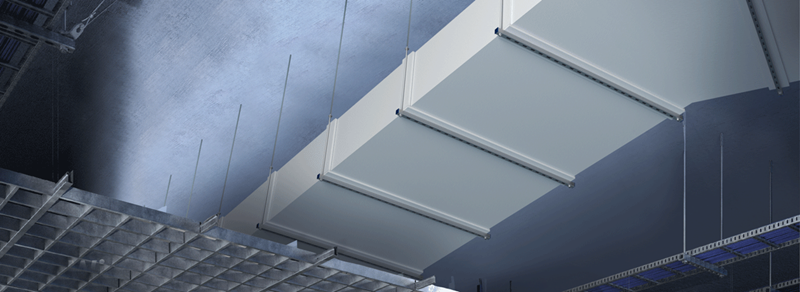

Promat offers a wide range of solutions for both ventilation and smoke extraction – for different operating pressures, sizes, orientations, configurations, even for partial fire exposures. The solutions developed by our technical experts can meet any fire resistance requirement from 30 minutes (FRL 30/30/30) up to 240 minutes (FRL 240/240/30).

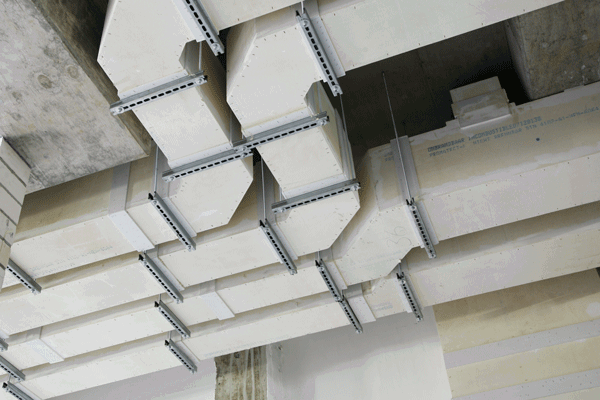

Traditionally, all ductwork used to be fabricated from steel. It required to be encased in a fire protection system when passing through a compartment wall or floor without the aid of a fire damper, or when used as part of a smoke extraction system. Promat has developed self-supporting systems without a steel liner, for example: PROMASIL® 1100 Super and DURASTEEL® which can match the leakage and air flow performance of steel ducts both for air duct and smoke extraction ducts.

Main advantages:

- No steel sheet ducts are required

- Single layer construction

- Dimensionally stable and moisture resistant

- Easy to cut to size, ex factory or on site

- Lightweight shaped sections

- Serviceable smooth surface, robust

- Tested according to the most severe international standards

- Supporting hangers, supports and their fixings can be unprotected

- Big dimensions (maximum dimensions are all classified by authorized laboratories)

- Roughness factor of the surface substantially identical to steel

The acoustic performances and the room temperature thermal insulation of Promat ductworks can be even improved using additional layer or layers of mineral wool.

For existing steel duct Promat Australia use the CAFCO® 300 vermiculite based firespray. DURASTEEL® boards can be used also for cladding of existing steel ducts.

How are the ventilation and smoke extraction ductworks tested?

Ventilation and smoke extraction ductwork is tested according to AS1530.4: 2014 Section 9

The test is divided into two fire scenarios, fire from outside of the duct and fire from inside of the duct. One duct is needed for each scenario and both scenarios have to be tested in horizontal and vertical direction.

The standard heating curve described in AS1530.4 is used for both scenarios.

The performance criteria are the following:

Structural Adequacy: Structural adequacy failure is deemed to occur when the duct collapses in such a manner that it can no longer fulfill its intended function

Integrity: integrity failure shall be deemed to have occurred if any of the following are observed:

- for internal fire , when hot gasses can pass to the unexposed side (except at the open end)

- for internal and external fire, where the criteria for failure of a penetration seal (Section 10) occur. These include use of cotton pad (for insulated specimens) and flaming on unexposed surface

Insulation: insulation failure if the temperature in any of the specified locations exceeds a temperature rise of 180 °K For external fire this includes the internal face of the duct inside the furnace. While for internal fire it is measured on the outside face of the duct outside of the furnace, along with the penetration seal at the wall joint.