Reduce your energy consumption & CO2 emissions by up to 60% with PromatInsulation solutions for your upstream steel production

|

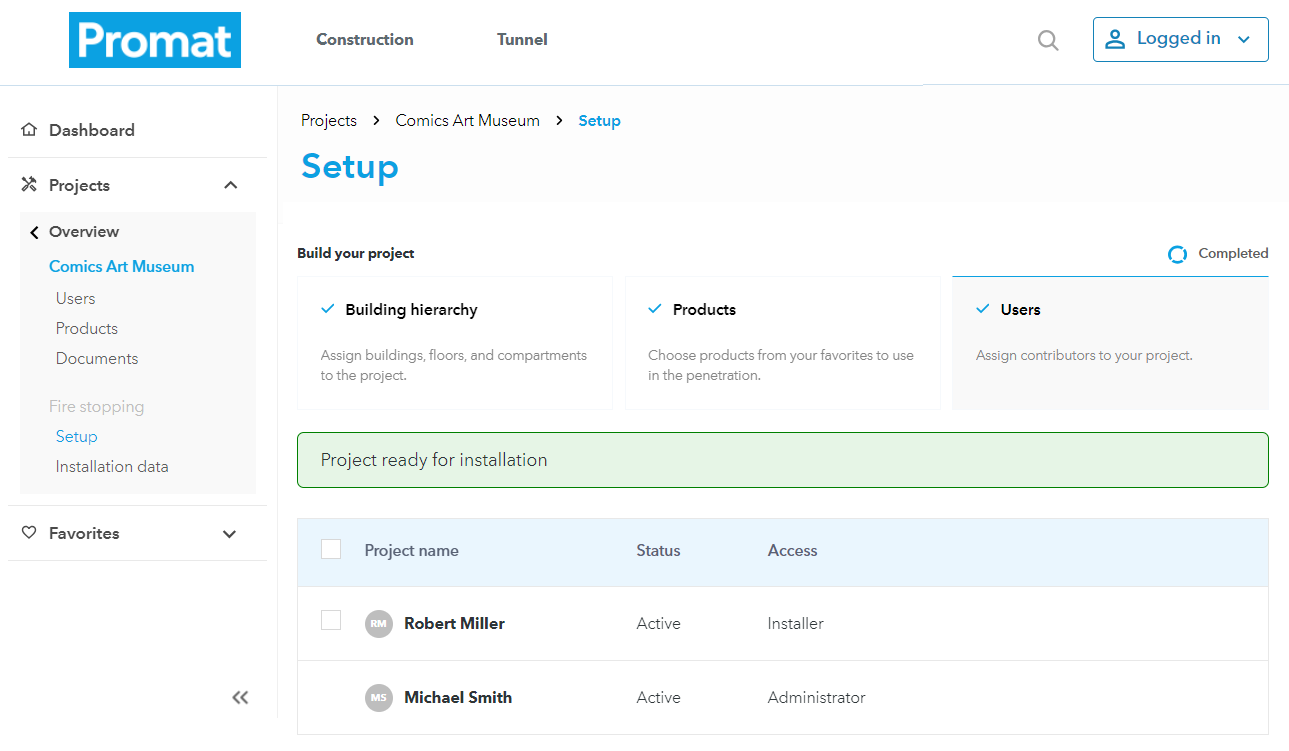

Improve steel plant efficiency with Promat’s backup insulation solutions

![]()

Reduction of heat loss by up to 60%

![]()

Energy cost saving between 20-50%

![]()

Reduction of CO2 emissions by up to 60%

![]()

increased capacity by up to 10%

Optimize energy savings by reducing temperature drop & shell temperatures

Optimize energy savings by reducing temperature drop & shell temperatures

Our materials excel in reducing molten metal temperature drops by up to 25% and lower the outer ladle shell temperature with up to 100°C, ensuring that ladles maintain optimal conditions and have an extended lifetime with up to 50%, while safeguarding the lives of those that operate them.

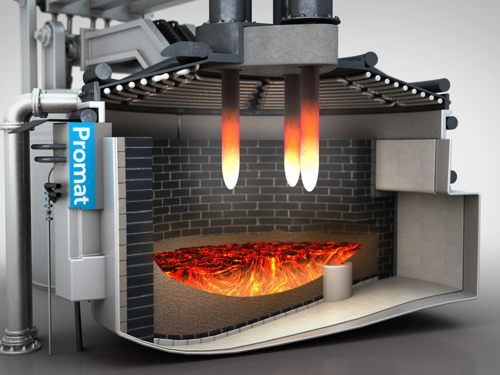

Cut CO2 and fuel costs in Electric Arc Furnaces by up to 60%

Cut CO2 and fuel costs in Electric Arc Furnaces by up to 60%

Our insulation materials enable precise temperature control throughout the EAF process, reducing energy consumption and CO2 emissions with up to 60% while guaranteeing consistent, high-quality steel production. Moreover, the extended lifespan of electrodes, achieved through minimized thermal stress, translates to reduced maintenance costs and increased overall operational efficiency which also aligns with your sustainability goals.

Contact us for a customized calculation on energy and CO2 savings.

Tundish excellence: Maximize steel output

Tundish excellence: Maximize steel output

Our insulation minimizes temperature variations to enhance the casting process and steel quality. This ensures optimal operation, boosts tundish equipment longevity, and minimizes downtime. Improve your tundish with our microporous insulation for up to 10% capacity increase and between 20-50% energy savings, tailored to your needs.