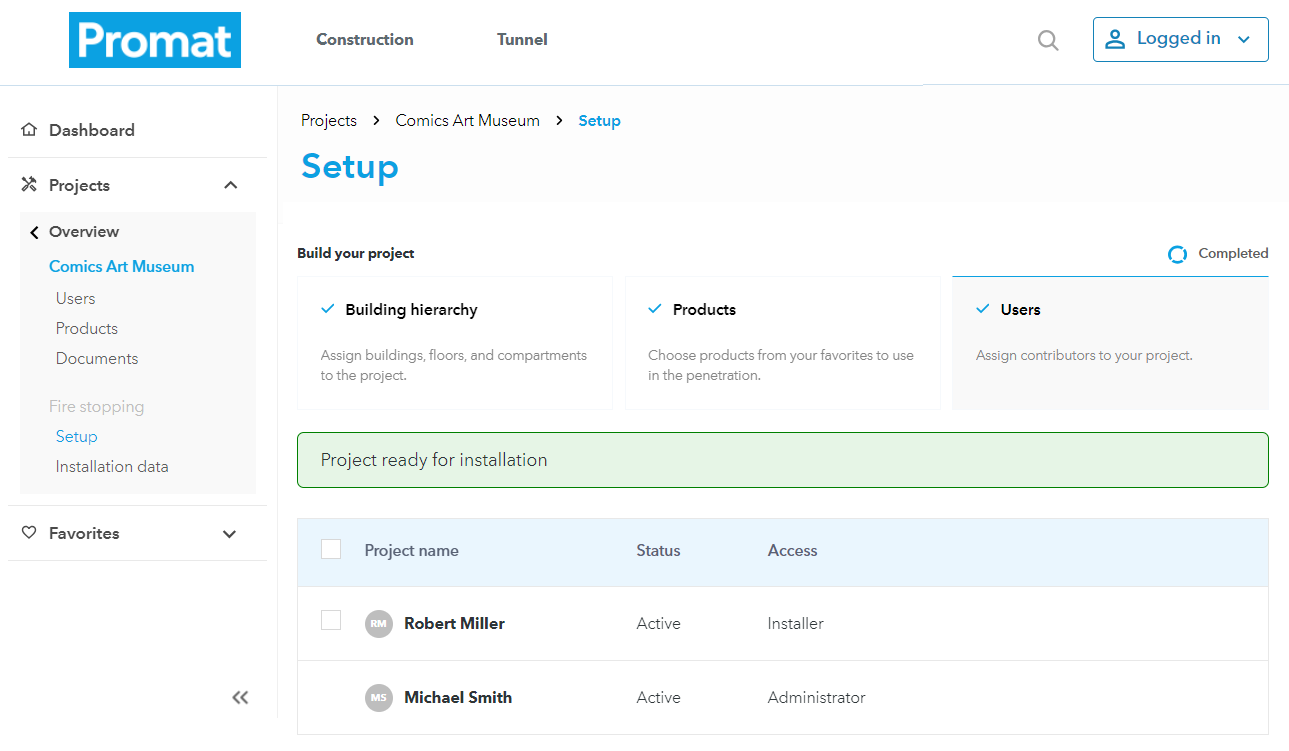

Configuración en 3 pasos

Crear jerarquía de edificios, añadir productos, invitar a instaladores

** What is the goal of structural protection?**

Making sure that the building structure, or parts of it, do not collapse or suffer serious structural damage during fire. Only under these conditions, the compartmentation can contain the fire, people can escape, the fire brigade can search the building for survivors and possibly fight the fire, and destruction of valuable assets is limited. Therefore, fire resistance of the loadbearing structure is the basic condition for fire safety of any building.

How is fire resistance defined?

Although the original objective is to avoid collapse or serious structural damage during an entire fire incident, national building codes define fire resistance of structures in time classes, e.g. 60, 90, 120, 180 or 240 minutes. In European standards, the fire resistance of a loadbearing structure is indicated with the letter R. For example, R120 means that a certain loadbearing element will not deform to the extent that it would jeopardise the stability of the structure during at least 120 minutes exposure to the standard fire curve.

Even if the probability that a fire would actually rage for (for example) 120 or even 240 minutes in the same location in a normal building is quite low, requiring such high fire resistance ratings effectively means that the probability of failure during fire is very low.

Although national building codes are different per country, they all require higher fire resistance classes for situations with higher risk, for example high rise buildings, hospitals, public buildings, etc. because more severe potential consequences (both in terms of safeguarding people’s lives and protection of the building and its contents) call for a lower probability of failure during fire, i.e. more fire protection. The fire resistance of a structure is determined by calculation standards such as the Eurocodes EN 1992-1-2 (concrete), EN 1993-1-2 (steel), EN 1994-1-2 (composite) and EN 1995-1-2 (timber). Whenever an unprotected structure does not meet the required fire resistance rating, fire protection must be applied. The fire resistance of the fire protected structure is determined by test methods, such as the EN 13381 standard series, BS 476, ASTM E119, etc.

Why does a steel structure need fire protection?

When steel is heated to temperatures of 400oC to 800oC, its strength gradually decreases. The stiffness of steel decreases already starting at 100oC. The reduction in strength and stiffness will cause large deformations and eventually collapse of building elements. As steel structures are generally slender and steel has a high thermal conductivity, they tend to heat up fast when exposed to fire. By applying a protective shell around the steel element or a fire shield such as a fire-rated suspended ceiling, the heating up of the steel is delayed and collapse can be postponed or avoided. ** What is the critical temperature of a steel structure?**

As steel gradually loses its strength during heating up, at a certain temperature the remaining strength of a steel element will be insufficient to carry the mechanical loads, and the element will collapse. This depends on the utilisation degree: the ratio of mechanical loads under fire conditions that act on an element vs. its strength at room temperature. The higher the utilisation degree of an element, the lower the temperature at which it would fail.

In order to avoid failure of a steel element, the steel temperature must remain lower than the theoretical temperature at which failure would occur. The maximum allowable temperature that is low enough to avoid failure is called the critical steel temperature. The lower the critical steel temperature, the more fire protection is needed.

The critical steel temperature for each element can be calculated by a structural engineer, or safe values (typically 450-620oC) can be used based on local regulations. For more information, please contact your local Promat office.

Why does a concrete structure need fire protection?

Although concrete heats up relatively slowly during fire, there are still ways that a concrete element can fail. The most common failure mechanism is when the concrete cover on the steel reinforcement is not thick enough to keep the reinforcement temperature down. This is often the case for old buildings and for buildings with very high fire resistance requirements. Fire protection can compensate for the lack of concrete cover thickness.

However, in cases where concrete is exposed to humid environments and/or potentially more severe fire temperatures, spalling of concrete poses an additional risk. Spalling of concrete causes quick and explosive detachment of layers of the concrete structure, usually occurring in the first 5 to 30 minutes of the fire, even if the temperature is still quite low, and exposing the steel reinforcement directly to the flames. In such cases it is necessary to apply fire protection to make sure that the concrete temperatures remain low and spalling does not occur.

Why does a timber structure need fire protection?

When a timber element is exposed to fire, the material starts to burn at the surface. Gradually a layer of char (burnt wood) is built up. Over time, the layer of char becomes thicker and the remaining cross section of timber decreases. The speed of this process depends mainly on the type of timber and the humidity (moisture content).

The remaining cross section must be able to carry the mechanical loads on the structure. Moreover, a small zone of this unburnt cross section just below the char is so hot that it doesn’t have strength left. Slowing down the heating and charring of the timber is key to extending its fire resistance. A fire protection material acts in two ways:

What is meant by “progressive collapse”?

The notion of progressive collapse is important for loadbearing structures. It means that when one element collapses, it triggers the collapse of a next element, and so on to bring down larger parts of the building or even a complete building. Progressive collapse can occur because if one element is weakened by the fire and fails, the loads (mainly the weight of the building and its contents) are redistributed to surrounding elements. It means that those surrounding elements undergo an increased load, which could in turn cause them to fail. Since the remaining elements decrease in number, the loads on those continue to increase. This process will often repeat itself, causing collapse potentially also beyond the part of the building affected by the fire.

What is a section factor?

When steel is exposed to fire, the thermal energy will cause the steel temperature to increase. The rate of temperature increase depends on the geometry of the steel:

The greater the exposed external surface of the steel element, the faster the thermal energy will flow into the steel element

The smaller the volume of the steel, the less thermal energy is needed to heat it up.

In European and British standards, both aspects are combined in the section factor, which is calculated by dividing the fire exposed external surface (in m2) by the internal steel volume (in m3). An alternative simple approach which gives the same outcome is to divide the exposed external perimeter (in m) by the cross-section area of the element (in m2). In ASTM standards, a similar approach is used where the calculation is based on the ratio between weight per linear foot (lb) and heated perimeter surface (inch).

Typically, section factors are in a range of 50m-1 to 300m-1. A low section factor means relatively slow heating, a high section factor means faster heating. Therefore, elements with a high section factor usually need thicker fire protection.

Even if a steel element is the same, the section factor can vary depending on some conditions:

Exposed surface: for beams under a concrete floor, only the sides and bottom of the beam are exposed to the fire. This is called “three sided exposure”. However a free standing column is exposed on four sides. Three or four sided exposure is reflected in the exposed surface which is used to calculate the section factor.

Box or contour protection: for sections with an H shape, the external exposed surface follows the contour of the H shape. However, if the fire protection consists of a rectangular box placed around the H shape, the external exposed surface is reduced to the size of the box. For intumescent paints and for sprays, the contour shape is relevant. For board protection, normally the box shape is used.

For more information, please contact your local Promat office.

What is the durability of structural fire protection?

The durability of a fire protection system, and therefore also the reliability over the life span of the building, depends on correct design and installation and on correct maintenance. When designing the building, it is crucial that the chosen fire protection system is resistant against weather conditions that it may be exposed to. Within the European Assessment Documents (EAD’s), the main weather resistance classes are Z2 (suitable for indoor dry conditions), Z1 (indoor humid conditions), Y (semi-exposed including freeze-thaw) and X (fully exposed), tested for a virtual service life of 10 or 25 years. Of course the real service life, even in the absence of ordinary maintenance, is much longer (generally multiplied by factor 2 or 3, according to European guidelines).

When installing the fire protection system, it is important that the installation instructions are carefully followed, and that for example water accumulation is avoided. Maintenance of a passive fire protection system is generally not required for indoor conditions. Whenever it is correctly designed and installed and not touched during the service life of the building, the fire performance remains the same. However if for example renovation works in the building lead to damage of the fire protection system, it needs to be correctly repaired.

For more information, please contact your local Promat office.

** What are the most common mistakes when designing structural fire protection?**

A correctly functioning fire protection system does not only depend on the availability of an independent test report or assessment, but also on the correct design where the fire protection system is used within the limits of that report.

The most common mistakes in the design are:

• Underestimating the actions on structures, including indirect actions, or overestimating the strength class of the steel, which leads to too high calculated critical steel temperatures.

• Not assessing the impact of localised fires, where temperatures can be very high, even if for a short time.

• Not considering the spalling effect for concrete structures.

• Using protective products outside their limits of applicability.

• Not properly evaluating test and classification tests of protective shields (suspended ceilings), whose functionality depends on many technical details.

• Not considering the robustness (or vulnerability) of the structures to be protected.

Apart from a correct design, the functioning of the fire protection system during fire depends equally on the correct installation.

What are the most common mistakes when installing structural fire protection?

Correct installation requires that the structure is accessible, that there is sufficient space to place and fix the fire protection system and that connections of different geometries don’t require very complex fire protection solutions. The common mistakes are different for various types of systems. For example for board protection, the use of noggins of the wrong material such as wood, or inaccurate spacing or positioning of staples that connect the boards. For sprays and paints the application conditions are crucial: adequate cleaning of the surface, compatibility with primers, and application only when ambient temperature, relative humidity and substrate temperature and drying times between coats are within the ranges given in the application instructions.

Te acercamos los datos más importantes del mercado para que puedas estar siempre informado