Promat Technical Support

Contact our technical support team with your questions on passive fire protection solutions, our products and systems or installation advice...

Steel is becoming an increasingly essential building material, and structural steel fire protection is in turn becoming an increasingly important aspect of modern construction. Steel is inorganic and classified non-combustible without special certification. Numerous research programs show that some types of fully stressed steel sections can achieve a 30 minute fire resistance without any additional fire protection materials being applied. However, these apply to a limited number of steel sections only, based on the allowable section factor Ap/V.

Structural steel loses a significant portion of its loadbearing capacity when it reaches a temperature of approximately 550°C. During many actual fire scenarios, temperatures in excess of 550°C can be attained within minutes. In fire tests, the performance of the test sample is measured according to an internationally recognized fire curve which tracks the relationship between time and temperature. Test sample temperatures of approximately 550°C in just 5 minutes, 850°C after 30 minutes and 1000°C after 90 minutes are not only typical but also underline the need for effective structural steel fire protection systems. The robust durability, dimensional stability and easy workability of the calci um silicate PROMATECT® building boards can be cut and fixed to clad or encase steel structural components in virtually any location of a modern building complex. Promat products and systems provide scientific solutions for structural steel in line with fire resistance code classification of 90 to 240 minutes.

Typical building regulations usually require certain elements of structure to be fire resistant for more than 30 minutes and up to a specified minimum period of time. The thickness of any fire protection material depends on a number of factors, such as:

To determine how these various factors affect the fire resistance, all Promat products and systems have been tested at accredited laboratories around the world to a variety of standards.

Tests carried out in accordance with these standards are performed on both loaded and unloaded beams and columns which are protected by fire protection material. Steel surface temperatures are monitored with thermocouples to assess the performance of the fire protection.

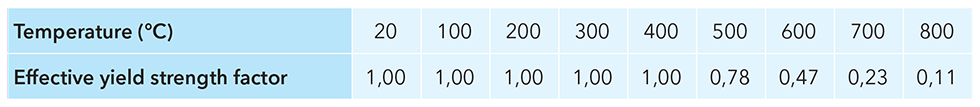

For example, at 700°C, the effective yield strength of Grade 43 (S275) steel is 0,23 x 275 = 63,25 N/mm2.

A range of unloaded sections are also tested to obtain data for analytical calculation, to measure exactly how much protection is needed for the most common steel sections and for providing fire resistance for different time periods.

The shape of the steel section can also play an important role when determining the required thickness of a protection material. For details on steel profiles, please consult your local Promat team. You will find some further information in our download section as well.

Contact our technical support team with your questions on passive fire protection solutions, our products and systems or installation advice...

Find the product datasheets, system brochures, Declarations of Performance, installation manuals and other documents you need to get the job done.

Follow #PromatAsiaPacific on social media: