Promat Technical Support

Contact our technical support team with your questions on passive fire protection solutions, our products and systems or installation advice...

Building fires are complex, scientific events, and so should the fire testing procedures be in order to provide us with a peace of mind. No two fire incidents are ever the same: the developments are dependent on the cause of the fire, the fire load, the structure in question, as well as its design. From a construction and building design perspective, this makes the job of specifying fire protection systems especially challenging.

Each country has its own regulatory framework in place to help specifiers identify which solutions are suitable for particular project requirements and use classes. However, the reality of a building or structural fire, and the complex way in which fire interacts with building materials, means that official regulations should only ever be used as the minimum baseline for fire protection systems. Consideration must also be given to any project-specific requirements which can often call for bespoke passive fire protection systems to be developed. In these cases, standard testing protocols will not apply.

What is needed then are testing processes that more closely mirror real-world conditions. These will ensure that specifiers have peace of mind that the system they choose meets the specific needs of individual buildings and their occupants.

The key question is how materials interact. How is the fire performance of a timber structure affected when it is abutted to a concrete frame construction? Regulations and building codes tend to deal with individual products, but fire is influenced by the performance and interaction of combined structural elements acting as a system/whole. Material providers have a vital role to play here. They need to create testing rigs that study the performance of products working in conjunction with each other.

This is about testing systems and test methods that match real-world conditions as closely as possible. This is particularly important for unusual or ground-breaking designs where materials are used in unexpected ways. Testing an individual element of construction, such as a standard steel beam, is not the same as understanding how the impressive steel vaulted ceiling at London’s King’s Cross Station will react and hold up structurally when exposed to fire.

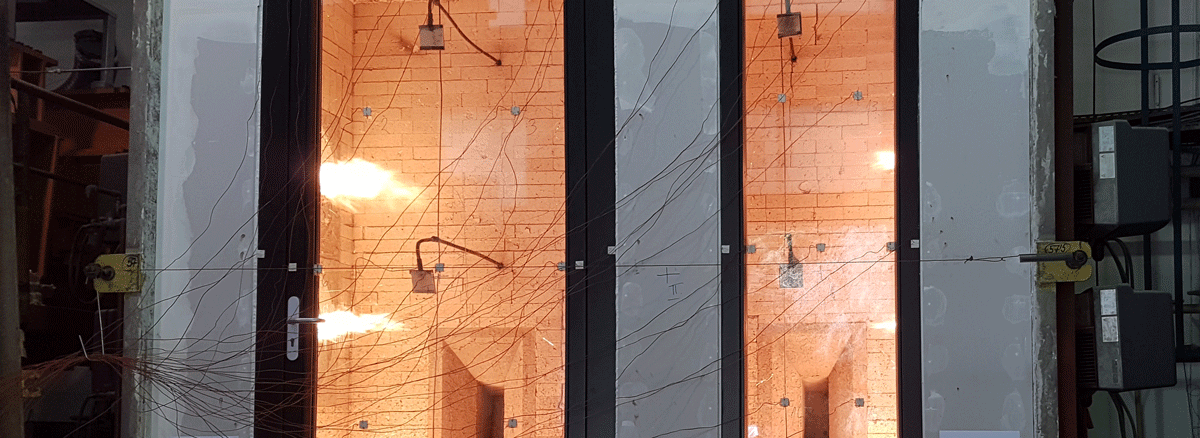

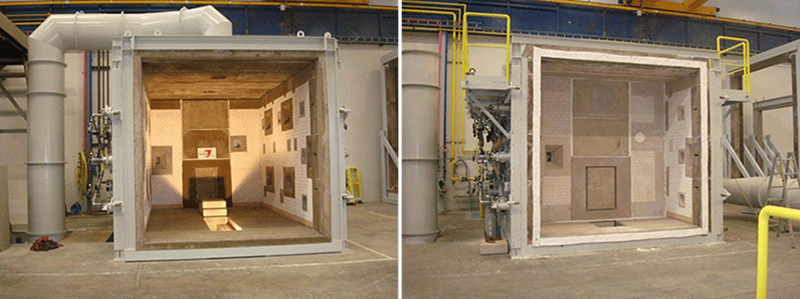

The partition system in a modern apartment or office will rarely mirror standard models and their reaction to fire. It will be penetrated by plug sockets, telephone wires or cables for satellite television, altering the way the overall system behaves during fire exposure. There will also be varying angles to consider and the relationship between walls and ceilings, as well as the positioning of load bearing elements, which will differ in each case. It is a vital component of fire safety management that these elements be accounted for during the development and testing of materials to ensure that they perform as expected, now and in the future when the occupants may add or change services. At Promat, we test full wall and ceiling systems with all of the potential service penetrations in situ.

Putting in place more robust fire testing processes is one thing. Knowledge also needs to be cascaded down the supply chain so that specifiers can understand why one fire protection system may be preferable over another and how the interplay of materials could impact the performance of their building.

It is incumbent on materials providers to share their expertise with supply chain partners. Likewise, specifiers should engage with manufacturers early on in a project’s inception when the design process can still be influenced.

Construction is continuing to evolve, with new ways of building, modern methods of construction and innovative materials coming to the fore. This is vital to help us deliver faster, more cost-effective and, ultimately, better buildings that meet the demands of 21st century life. However, if we are to continue pushing the boundaries of good design and building practices, then we need to make sure that our approach to material testing and development keeps up with such changes.

Developing a better understanding of how different materials perform together is vital. For both new or traditional products, better accounting for the stresses they are likely to be put under in real-world conditions is key. This will help to ensure that the buildings we construct in future are safe and help us to fulfil the creative vision of architects and specifiers while offering peace of mind for building users.

Contact our technical support team with your questions on passive fire protection solutions, our products and systems or installation advice...

Find the product datasheets, system brochures, Declarations of Performance, installation manuals and other documents you need to get the job done.

Follow #PromatAsiaPacific on social media: