Promat Technical Support

Contact our technical support team with your questions on passive fire protection solutions, our products and systems or installation advice...

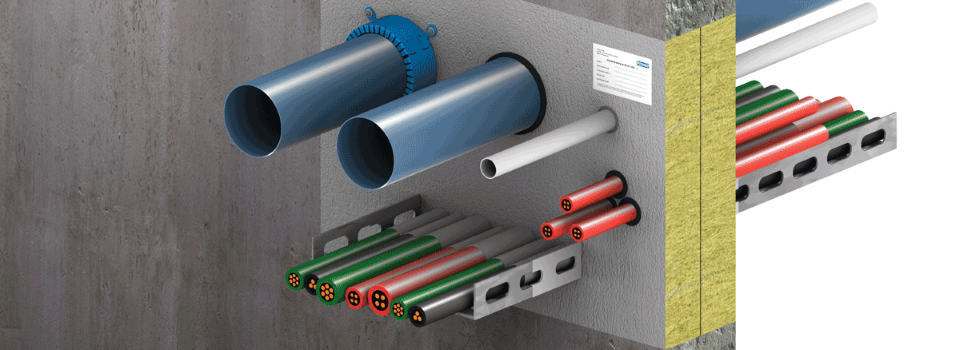

This is the third article in our series. In the first and the second part we covered topics like penetration seals of metal pipes, non-combustible pipe insulations (CS, CI, LS or LI arrangements), possible pipe end configurations (U/U, U/C, C/U, C/C), hanging and support distances of assemblies, pipes made of combustible materials, penetration seals of multi-layer composite pipes and combustible pipe insulations.

Now, it is time to look at some of the most important considerations, each construction company needs to take and which are not related to Promats products.

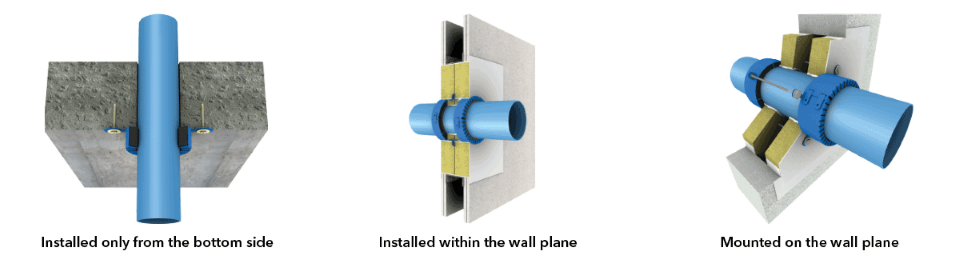

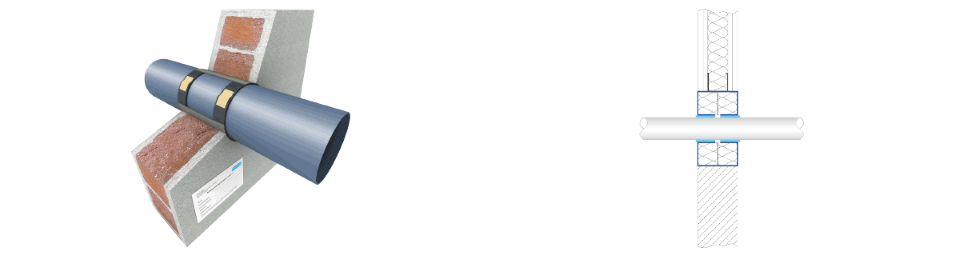

As a general rule, in case of wall penetrations (except for shaft walls) a fire stopping collar, wrap or acrylic must be installed on both sides of the penetration. In case of floor penetrations, the mentioned products must be installed usually from the bottom side only, but there are exceptions the PROMASTOP®-W fire stopping wrap must be installed in a cross laminated timber (CLT) floor on both sides.

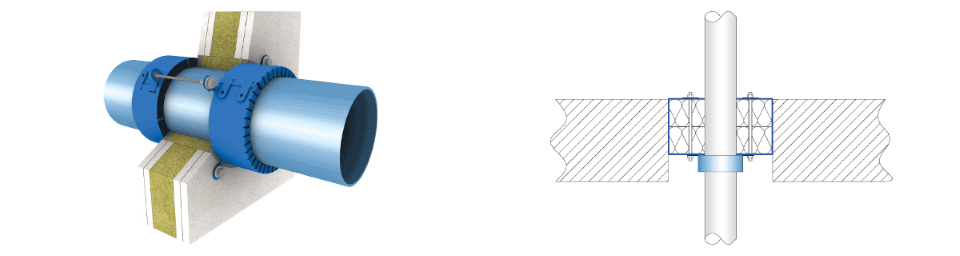

After careful examination of the data we obtained from tables in the previous articles, we might conclude that PROMASTOP®-FC fire stopping collars are installed on walls/floors (surface-mounted) or in walls/floors (built-in). Theoretically all collars with stable metal housing could be installed both by extending from the penetration plane (surface-mounted) and fitted into the penetration plane (built-in). Please note that the collar may only be used according to the classification in the test arrangement.

There are some interesting focus points to apply a fire collar correctly:

Sometimes collars have to be applied in special situations, where the amount of intumescent inlay with an installation depth of 30 mm, (PROMASTOP®-FC3) is no longer sufficient. Promat therefore developed the larger PROMASTOP®-FC6 and PROMASTOP®-FC15 fire-stopping collars, suitable for installation depths of 60 mm and 150 mm. Special applications:

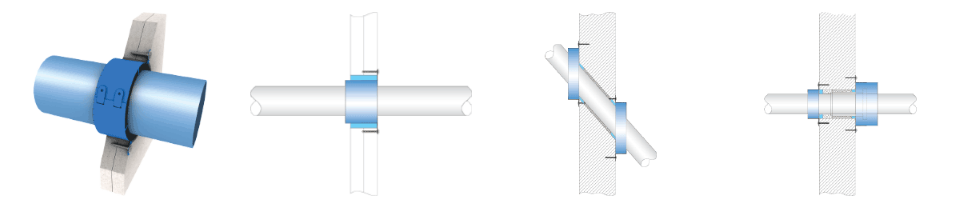

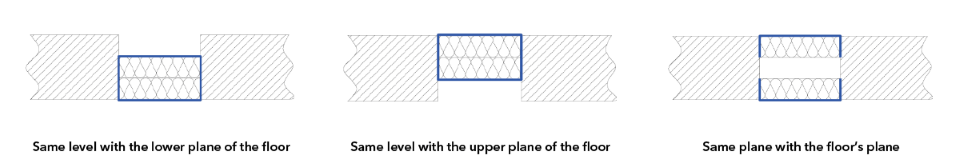

Penetration seals without the use of fire stopping collars are very economical solution, as there’s no need for expensive collars with stainless steel housing, although they have their limitations. A fire stopping wrap can be used as built-in application only; combination with tested soft batt penetration only (wraps and soft penetrations aren’t variable). The PROMASTOP®-W wrap is classified in PROMASTOP®-CC and PROMASTOP®-I soft batt penetrations for walls and floors. The wrap can only be installed within the plane of the wall or floor; it might protrude up to 5 mm from the plane of the surface and it must not be applied with the coating, which forms part of the soft batt penetration (the coating would prevent the required foaming of the wrap by means of the cooling and thermal insulation effect). The wrap must be installed in such a way as to make its edge into the same flat plane of the batt’s lower plane with floor penetrations, and with wall penetrations it must be adjusted to the planes of both sides of the batt (considering the previously mentioned 5 mm protrusion).

The number of layers (depending on the material and the outer diameter of the pipe) must be considered (e.g. fire classification EI 120-U/C is ensured with two layers of PROMASTOP®-W wrap in 2 x 50 mm PROMASTOP®-CC soft penetration for PVC-U, PE-HD, ABS, SAN+PVC, PP-H and PP-R pipes up to 110 mm outer diameter).

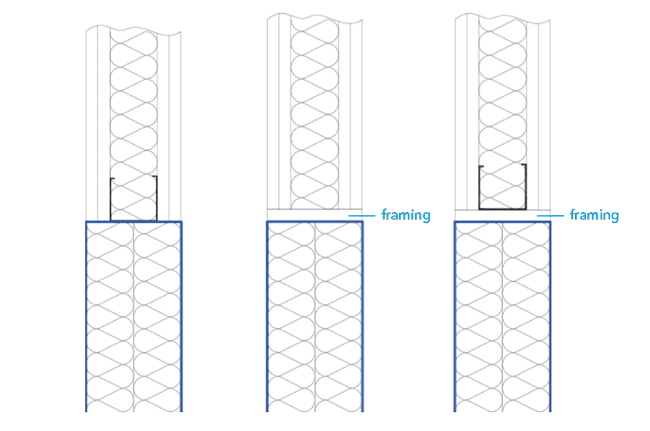

A frame must be established around the penetration opening in flexible walls, as mineral wool boards of the soft batt penetration cannot be properly wedged in if there is no stable barrier surface. Edges can be established in three ways for Promat penetrations:

Note! In case of wooden studs, a minimum of 100 mm spacing must be established between the hole of the penetration and the wooden support, the gap between the wooden support and the penetration must be sealed by a minimum of 100 mm insulation of A1 or A2 reaction to fire classification (according to EN 13501-1 standard).

There are different ways to install the required 2 x 50 mm thick mineral wool insulation into floors to achieve EI 90 classification:

The test arrangement of the chosen product must be taken into consideration. Promat’s soft batt penetration systems, PROMASTOP®-I or PROMASTOP®-CC, are classified for all three arrangements.

The minimum distance between each service and the service’s distance from the building structure is defined in the most common soft batt penetration; it is not possible to install them more densely than the arrangement defined in the test. The following table includes some examples.

| Object | Minimum distance (mm) |

| Non-combustible insulation – Non-combustible insulation | 0 |

| Non-combustible insulation – Supporting construction/component framing | 0 |

| Non-combustible insulation – PROMASTOP®-IM CJ21 | 0 |

| Non-combustible insulation – PROMATECT® ducts | 0 |

| Non-combustible insulation – PROMASTOP®-FC | 0 |

| Cables, cable trays – Supporting construction/component framing | 0 |

| Cables, cable trays – Cables, cable trays | 0 |

| Cables, cable trays – PROMASTOP®-FC | 0 |

| Cables, cable trays – PROMASTOP®-IM CJ21 | 0 |

| PROMASTOP®-FC – PROMASTOP®-FC | 0 |

| PROMASTOP®-FC – PROMASTOP®-IM CJ21 | 0 |

| PROMASTOP®-FC – PROMASEAL®-A | 0 |

| PROMASTOP®-FC – PROMASEAL®-AG | 0 |

| PROMASTOP®-FC – PROMATECT® ducts | 0 |

| PROMASTOP®-FC – Supporting construction/component framing | 0 |

| PROMASTOP®-W – Non-combustible insulation | 0 |

| PROMASTOP®-W – PROMASTOP®-W | 0 |

| PROMASTOP®-W – PROMASTOP®-IM CJ21 | 20 |

| PROMASTOP®-W – PROMASTOP®-FC | 0 |

| PROMASTOP®-W – PROMATECT® ducts | 30 |

| PROMASTOP®-W – PROMASEAL®-A | 0 |

| PROMASTOP®-W – PROMASEAL®-AG | 0 |

| PROMASTOP®-W – Supporting construction/component framing | 0 |

| PROMASTOP®-IM CJ21 – PROMASTOP®-IM CJ21 | 0 |

| PROMASTOP®-IM CJ21 – PROMASEAL®-A | 0 |

| PROMASTOP®-IM CJ21 – PROMASEAL®-AG | 0 |

| PROMASTOP®-IM CJ21 – Supporting construction/component framing | 0 |

| Between all other objects not further defined | 100 |

The whole cross section of assemblies (pipes including their insulations, cables including their support structures) within the large penetrations (soft batt, hard mortar, pillows, bricks) cannot exceed 60% of the penetration’s cross section.

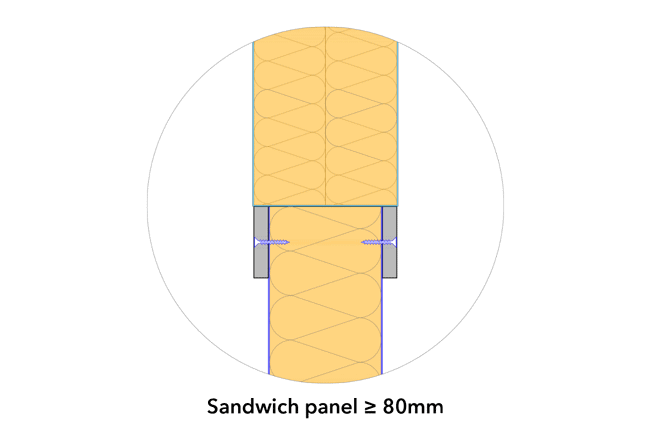

The penetration seals of pipes or cables in sandwich panels has to be tested specifically. Promat has classified penetration systems with the following sandwich panel walls:

The tested panel ArcelorMittal Pflaum Rockwool Panel FO-010-10-80 / 1000 must be ≥ 80 mm thick, with a frame made from PROMATECT®-100 fire protective boards (thickness ≥ 10 mm) installed around the opening using drywall screws (spacing ≤ 200 mm). PROMATECT®-100 boards must cover the edge area of the opening over a width of ≥ 50 mm.

This concludes our three-part article series on pipe penetration seals. The topic is wide and complex and requires a lot of knowledge and experience. Therefore, we kindly invite you to contact our technical team, by using the link below. We will be happy to answer any questions you might have regarding your projects. Let us design safer buildings together.

In one of our future topics we plan to focus on electric systems of the buildings, because cable installations are exposed to special risks and are worth some special attention. The planned final part of our fire-stopping series of articles describes penetration seals for cables, cable bundles and linear joints (gaps).

Contact our technical support team with your questions on passive fire protection solutions, our products and systems or installation advice...

Find the product datasheets, system brochures, Declarations of Performance, installation manuals and other documents you need to get the job done.